Posted: April 14, 2021

Source: ©iStock/iamfat42

Solar-powered water treatment can significantly reduce industrial manufacturers’ water and energy footprints and turn municipal water treatment plants into energy distributors. An example of this, a demo plant in Spain producing renewably sourced hydrogen and oxygen from wastewater, was presented by Christoph Brunner, chair of IEA SHC Task 62 – Solar Energy in Industrial Water and Wastewater Management, at an IEA SHC Solar Academy webinar in March. This article summarises key parts of his presentation at the event, organised jointly with the International Solar Energy Society (ISES). The entire webinar is also available online: https://www.iea-shc.org/solar-academy/webinar/solar-energy-in-industrial-water-wastewater-management

Challenge

Manufacturers are among the largest consumers of water and energy. In 2014, they were responsible for 10 % of global water withdrawals. This causes high disposal costs and a loss of resources found in wastewater, key reasons why our Task 62 research platform focuses exclusively on industrial water and wastewater management. It should also be noted that about 30 % of municipalities’ total energy demand, e.g., around 40 kWh per resident and year, is used to power those plants.

Figures: IEA SHC Task 62

Objectives

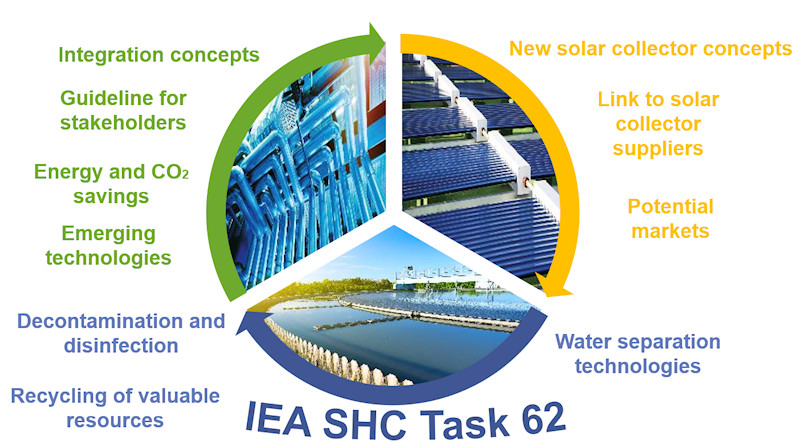

Similar to the United Nations’ Nexus concept, which combines Water-Food-Energy, our Nexus links Solar Energy-Water-Industry. We have targets for all three. Regarding Solar Energy (marked in yellow in the chart above), we want to closely work with industrial suppliers to develop new collector ideas and identify new potential markets for their technology. In the area of Water (blue), our aim is to examine and make use of solar-driven technologies to reduce wastewater volumes and recycle valuable resources. And when it comes to Industry (green), we aim to identify emerging technologies that are not state of the art yet but have great potential. We will also develop new ideas for solar process integration and write decision-making guidelines supporting stakeholders in selecting the right technology that can meet their individual needs.

Solar technologies

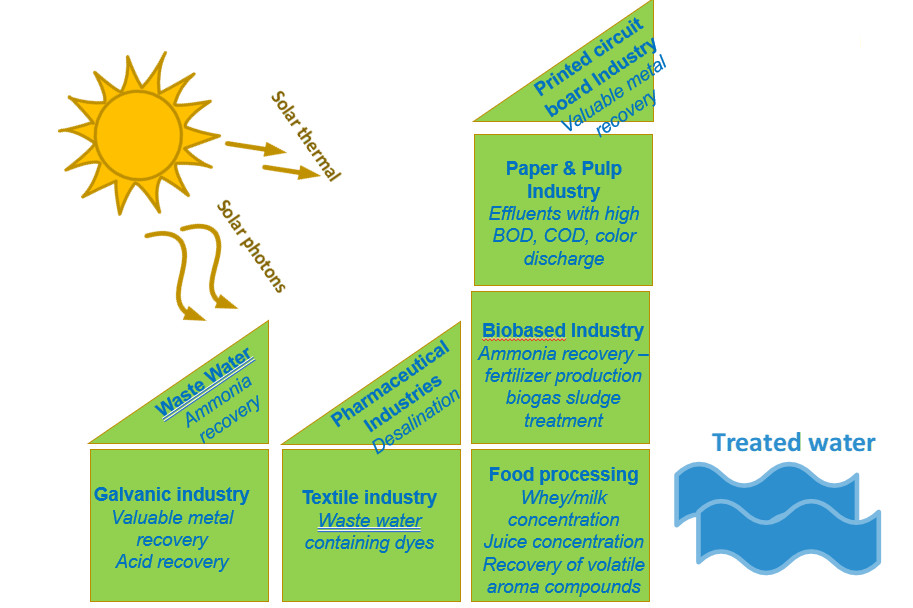

We see solar energy as a reliable ally in reducing energy and water demand from many industrial applications. We are following two very different approaches to meet our objectives. Typically, we use the solar heat generated by collectors to clean water via membrane distillation, vacuum evaporation or pervaporation. Some task colleagues also use solar photons directly to purify water by way of photocatalysis, decontamination or disinfection.

Potential industrial applications

We see great potential for solar to improve water treatment in many industries:

- In the galvanic industry, where recovering metals and chemicals is essential.

- In the textile industry, where treating wastewater from dyeing processes is an urgent need.

- In the food industry, to support the manufacture of concentrated whey, milk and juice and the recovery of aroma compounds, such as phenols, or volatile components, e.g., alcohols.

- In the biobased industry, with the two most important applications being the recovery of ammonia from residues produced by biogas plants or industrial or municipal wastewater treatment plants. The ammonia is then used to make fertilizer or produce electricity in fuel cells.

- In the pulp and paper industry, where solar technologies show great potential for reducing COD, that is Chemical Oxygen Demand, an indicator of wastewater pollution.

- In the pharmaceutical industry, where we see great potential for using solar-driven desalination, as the high salt concentrations found in process water often cause problems in pipes, valves and pumps due to corrosion, as well as malfunctions in the operation of biological waste water treatment plants.

- In the printed circuit board industry, as companies’ wastewater additionally contains valuable metals, for example, gold or palladium, resources definitively worth recovering.

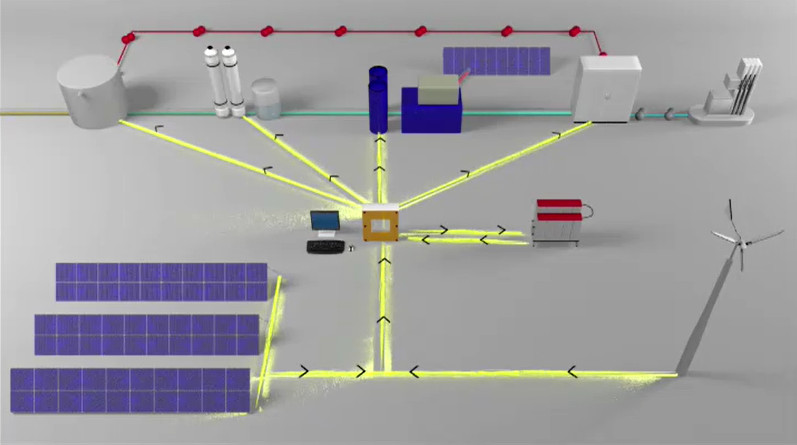

Renewable energy-driven sewage treatment plant in Spain built and tested during EU project Greenlysis

Demonstrators

The potential of wastewater treatment plants to become future energy distributors is huge. For example, the clean water leaving these plants can be used as an energy source for heat pumps, to produce thermal energy at temperatures suitable for municipal district energy networks. Furthermore, biogas, produced by the sludge in a digester, can drive a combined heat and power plant to support municipal energy generation. An impressive demonstration system of this kind was built during an EU project called Greenlysis. It uses 100 % renewable energy (solar thermal, PV and wind) to produce hydrogen and oxygen from wastewater (see the image above). Greenlysis also included a solar field fuelling a membrane distillation unit. Tests have proved that the maximum amount of distillate is produced when temperatures at the evaporator inlet are above 70 °C and not higher than 25 °C at the condenser inlet. This way, an adequate temperature gradient is achieved between the evaporator and condenser channels.

Outlook

The energy-water-industry nexus is obviously of key concern when crafting GHG emission reduction strategies. The optimisation of membrane separation technologies to recover nutrients and other waste products will be part of our future research agenda. Additional best practice examples will also be very important to turn new ideas into practice. If you have further insights into the above-mentioned topics and would like to share them with us, we would be happy to hear from you. You can email Christoph Brunner at c.brunner@aee.at

More information: